Magnetic vs Pneumatic Workholding for Thin Sheet Aluminium

Wolemba: PFT, Shenzhen

Ndemanga

Makina olondola a aluminiyumu woonda (<3mm) amakumana ndi zovuta zogwirira ntchito. Kafukufukuyu akufanizira maginito ndi ma pneumatic clamping system omwe amayendetsedwa ndi CNC milling. Zoyeserera zinaphatikizapo kusasinthasintha kwamphamvu ya clamping, kukhazikika kwa kutentha (20°C–80°C), kugwedera kwamphamvu, ndi kupindika kwa pamwamba. Pneumatic vacuum chucks amasunga kusalala kwa 0.02mm kwa mapepala a 0.8mm koma amafunikira malo osindikizira osasunthika. Electromagnetic chucks idathandizira kupeza ma 5-axis ndikuchepetsa nthawi yokhazikitsira ndi 60%, komabe mafunde a eddy adayambitsa kutentha komweko kupitilira 45 ° C pa 15,000 RPM. Zotsatira zikuwonetsa makina a vacuum amakhathamiritsa kutsirizika kwa mapepala> 0.5mm, pomwe mayankho a maginito amathandizira kusinthasintha kwa ma prototyping mwachangu. Zoperewera zimaphatikizapo njira zosakanizidwa zosayesedwa ndi njira zina zomata.

1 Mawu Oyamba

Ma sheet a aluminiyamu opyapyala opangira magetsi kuchokera kumlengalenga (zikopa za fuselage) kupita ku zamagetsi (zopanga zakuya kwa kutentha). Komabe, kafukufuku wamakampani a 2025 akuwonetsa kuti 42% ya zolakwika zolondola zimachokera kumayendedwe ogwirira ntchito pamakina. Zingwe zamakina wamba nthawi zambiri zimapotoza mapepala a sub-1mm, pomwe njira zopangira tepi sizikhala zolimba. Kafukufukuyu amapeza mayankho awiri apamwamba: ma electromagnetic chucks leveraging control remanence system ndi ma pneumatic system okhala ndi multi-zone vacuum control.

2 Njira

2.1 Mapangidwe Oyesera

-

Zida: 6061-T6 aluminiyamu mapepala (0.5mm/0.8mm/1.2mm)

-

Zida:

-

Maginito: GROB 4-axis electromagnetic chuck (0.8T field intensity)

-

Mpweya: SCHUNK vacuum mbale yokhala ndi 36-zone manifold

-

-

Kuyesa: Kutsika kwapamtunda (laser interferometer), kujambula kwamafuta (FLIR T540), kusanthula kugwedezeka (3-axis accelerometers)

2.2 Ma Protocol Oyesa

-

Kukhazikika Kokhazikika: Yezerani kupatuka pansi pa 5N lateral mphamvu

-

Kukwera Panjinga Yotentha: Jambulani kutentha kwa kutentha panthawi ya mphero (Ø6mm mapeto mphero, 12,000 RPM)

-

Dynamic Rigidity: Kuwerengera kuchuluka kwa kugwedezeka kwa ma frequency a resonant (500-3000 Hz)

3 Zotsatira ndi Kusanthula

3.1 Kuchita kwa Clamping

| Parameter | Pneumatic (0.8mm) | Magnetic (0.8mm) |

|---|---|---|

| Avg. Lakwitsidwa | 0.02 mm | 0.15 mm |

| Kukhazikitsa Nthawi | 8.5 min | 3.2 min |

| Max Temp Rise | 22°C | 48°C |

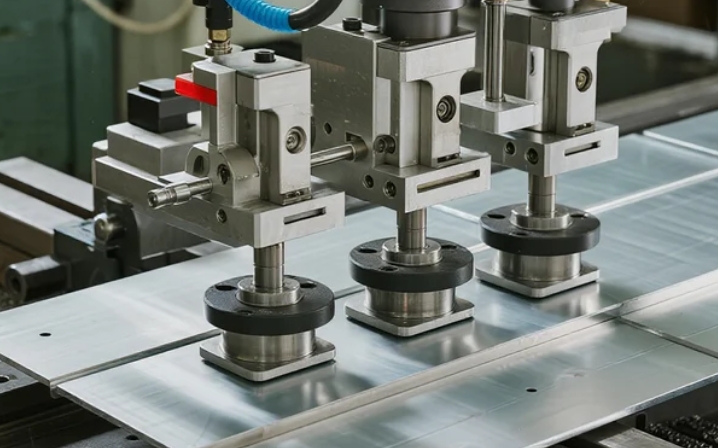

Chithunzi 1: Makina a vacuum amakhalabe <5μm kusinthika kwapamtunda panthawi yamphero, pomwe kupopera kwa maginito kunawonetsa kukweza m'mphepete kwa 0.12mm chifukwa chakukula kwamafuta.

3.2 Makhalidwe Ogwedezeka

Pneumatic chucks adachepetsa ma harmonics ndi 15dB pa 2,200Hz - yofunika kwambiri pakumaliza ntchito. Kugwira ntchito kwa maginito kunawonetsa 40% matalikidwe apamwamba pazida zogwiritsa ntchito pafupipafupi.

4 Nkhani

4.1 Zosintha zaukadaulo

-

Ubwino wa Pneumatic: Kukhazikika kwapamwamba kwamafuta ndi kugwedera kwamadzi kumatengera ntchito zololera kwambiri ngati zoyambira zowonera.

-

Magnetic Edge: Kukonzanso mwachangu kumathandizira malo ogulitsa ntchito omwe amagwira ntchito zosiyanasiyana.

Zoletsa: Mayeso omwe sanaphatikizidwe ndi mapepala okhala ndi perforated kapena mafuta pomwe mphamvu ya vacuum imatsika> 70%. Mayankho a Hybrid amafunikira maphunziro amtsogolo.

5 Mapeto

Kwa makina owonda kwambiri a aluminiyamu:

-

Pneumatic workholding imapereka kulondola kwambiri kwa makulidwe> 0.5mm okhala ndi malo osasunthika

-

Makina a maginito amachepetsa nthawi yosadula ndi 60% koma amafunikira njira zoziziritsa kuwongolera kutentha

-

Kusankhidwa koyenera kumadalira pa zomwe mukufuna kuchita ndi zololera

Kafukufuku wam'tsogolo akuyenera kufufuza ma clamp osinthika a haibridi ndi mapangidwe ocheperako a electromagnet.

Nthawi yotumiza: Jul-24-2025